#OEM&Suppliers

@ OasisSales is where Wire Harness + the digital enterprise meets tomorrow

Increases in E/E design complexity demand powerful tools

Electrical Design cannot be done in isolation.

Why Digitalize E/E Systems and Wire Harnesses?

Our Capital Solution is a unique, model based software for OEM operations who want to boost competitiveness & profitability. Developed by industry experts in one of the world’s largest companies, it creates a digitalized “design through manufacturing engineering” flow with powerful automation, simulation and integration. Capital will transform a company’s engineering prowess & manufacturing efficiency.

Digitalization commonly delivers clear business benefits:

- Improved design quality, because designs can be simulated and verified versus requirements.

- Improved efficiency and reduced costs, because processes and the products themselves can be optimized more easily.

- Compressed timescales, because assets can be re-used and complex tasks can be automated.

- Enhanced innovation, because engineering talent can be liberate to focus on creative problem solving.

Reduce the cost of 1st time quality

Electrical systems are very complicated. Without digitalization Simulation, verification and traceability is difficult.

Create cheaper, more efficient, functional products

Harness manufacturing is a complex process. Without digitalization optimization for cost, weight, space,and other targets cannot be achieved.

Reduce development costs and cycle times

Design change is constant. Without digitalization design changes are difficult to execute, and accurately pass through to manufacturing and documentation.

Capture intellectual property currently stored as tribal knowledge

Creative engineers want to be liberated from mundane tasks. Without digitalization assets cannot easily be re-used or re-purposed. Corporate IP cannot be leveraged.

Digitalization in action

Electrical and mechanical design are intimately linked. Failure to create a managed digital thread between these disciplines has caused very costly problems.

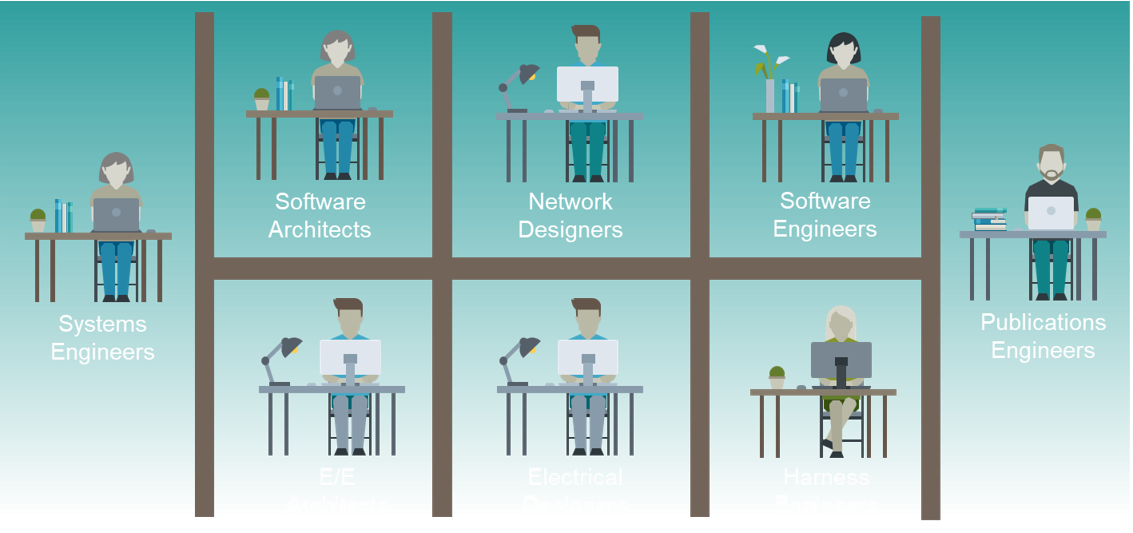

Electrical systems engineering is not just electro mechanical in nature. Adjacent disciplines include requirements engineering, systems modeling, product planning, electronic design, platform verification, workflow orchestration, supplier integration, manufacturing execution, and lifecycle services.

Our Solution is a truely connected solution for Design Engineering, Product Engineering, Formboard, Manufacturing, Sub-Assemblies, BOM & Costing, Line Balancing and Work Instructions.

- Quote-to-production cycle time reduction 30%

- Fault Diagnosis Time Reduction 40%

- Electrical Design Time Reduction 50%

- Service Documentation Time Reduction 80%

- ECO Reduction 90%

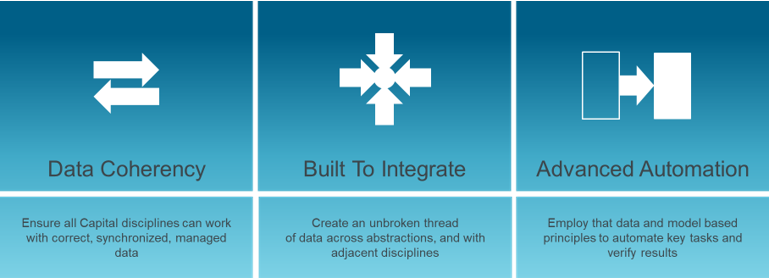

True model-based portfolio that is built on 3 technology principles:

These principles are strong differentiators – Data Coherency, Built to Integrate & Advanced Automation:

>>No competitive portfolio has comparable depth of capability.

Functionality examples leveraging these principles include:

- Electrical simulation & functional verification.

- Generative wiring design & configuration optimization.

- Manufacturing SBOP, costing & operator instructions generation.

- Documentation generation.

- Traceability & impact analysis.

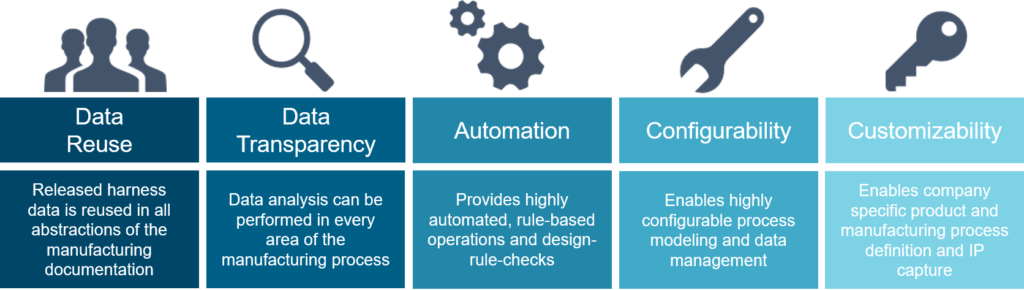

True model-based enterprise

Electrical design optimization, verification, manufacture, documentation, and maintenance is now only feasible using sophisticated methods. Model based tools deliver substantial automation. Errors and inefficiencies are avoided, and engineers freed for creative problem solving.

Functionality examples leveraging these principles include:

- Automate difficult or repetitive tasks.

- Simulate, verify, or optimize designs and manufacturing processes.

- Efficiently meet compliance mandates.

- Re-use or re-purpose assets while protecting IP.

- Improve after sales operations.

- Foster engineering innovation.

Wire harness engineering solutions

The complexity and product variation of electrical distribution systems cannot be managed by human beings alone. Sophisticated software solutions are indispensable.

Model based tools deliver substantial automation avoiding engineering errors & allowing engineers to innovate instead of performing mundane tasks.

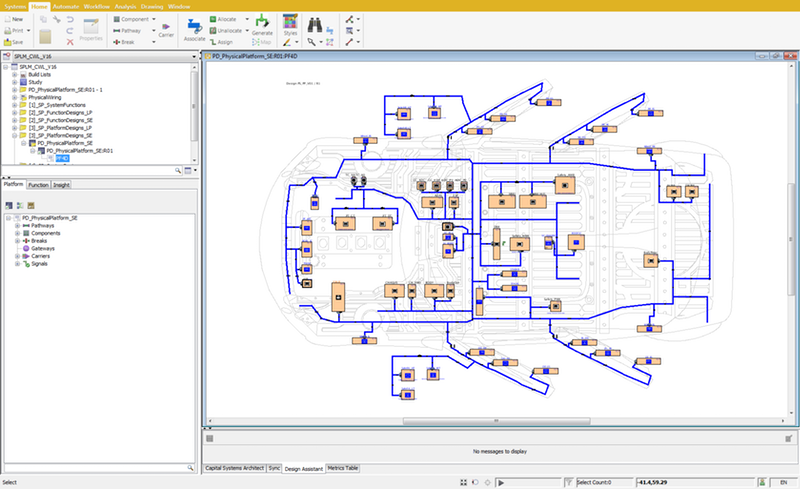

DEFINE: Capital Systems

Capital Systems Architect and Modeler tools help engineers capture function characteristics and connectivity, and develop optimized implementations within platforms. Software, hardware, network, and electrical functions can be managed together in a lightweight environment that allows these disciplines to collaborate easily.

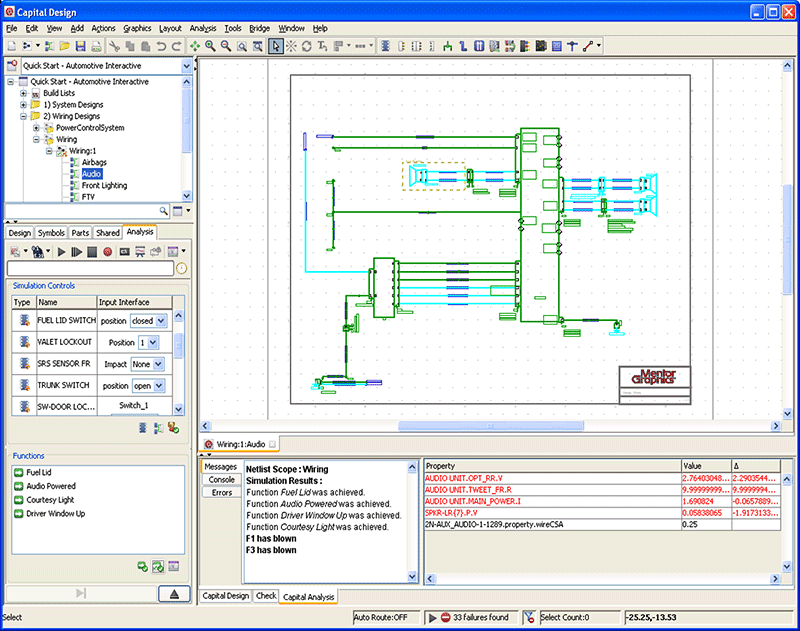

DESIGN: Capital Logic Designer

Capital Logic Designer is a powerful graphical and design-management environment for authoring both logical connectivity designs (signals), and physical wiring designs (wires, splices, multicores, etc).

Capital Logic Designer may be used to design both sub-systems and to accomplish interactive system integration, i.e. the merging of multiple sub-systems into the physical structure.

Capital Logic Designer is more than a schematic design tool, it provides a foundation for a complete Capital electrical design flow: from logical concept design through to harness design (using Capital Harness Designer).

Standard capabilities include an easy to use DC simulation facility, a powerful parts library, a symbol authoring facility with pre-defined standard symbols, and extensive project and data management tools that automate many of the time-consuming & error-prone tasks that are usually performed manually, by a designer.

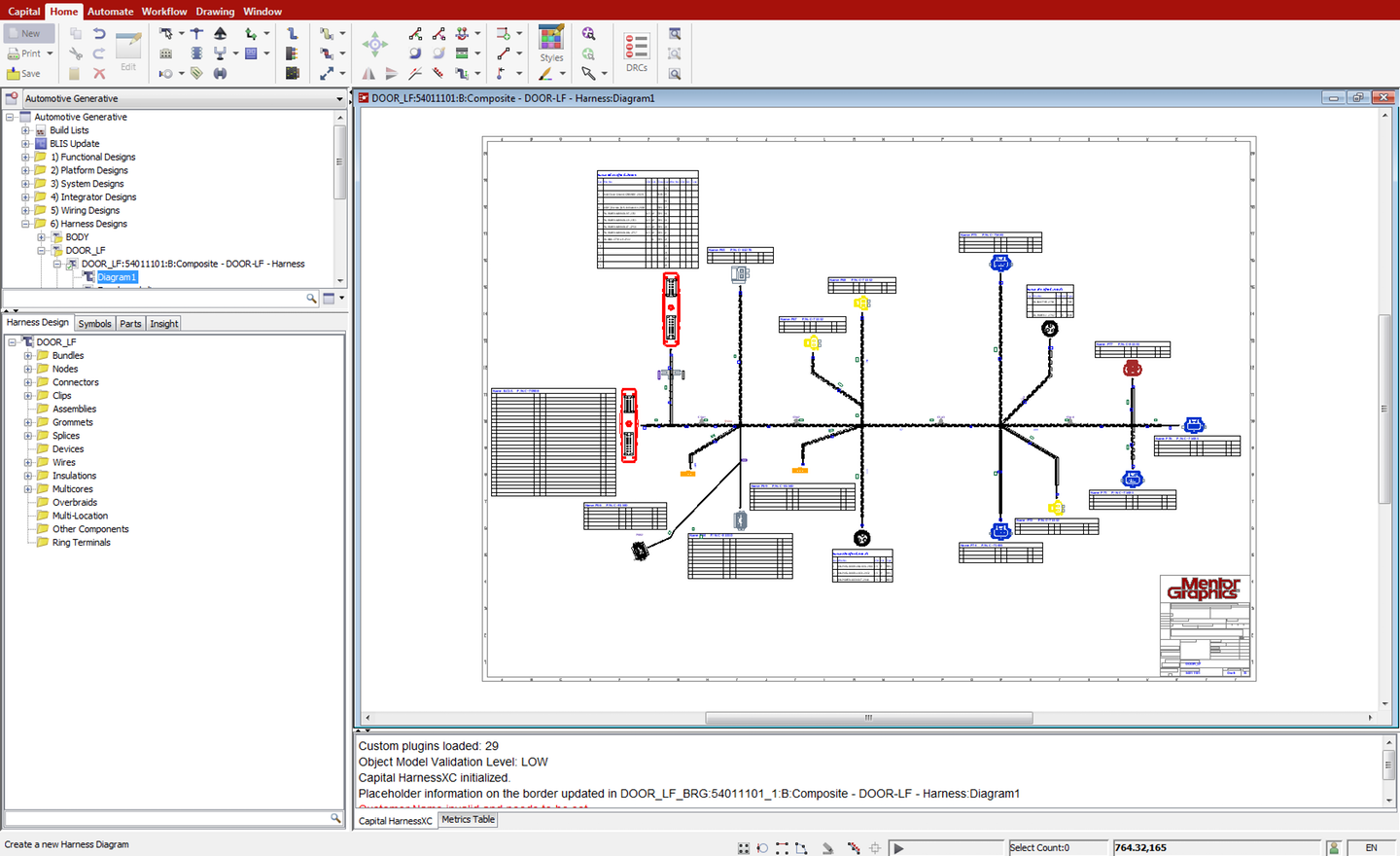

DESIGN: Capital Harness Designer

Capital Harness Designer enables harness engineers to create fully detailed, validated and manufacturing-ready harness designs rapidly and easily.

Conceived from the ground up to be highly configurable, companies can tailor the tool to meet their precise needs, both in terms of graphical outputs and they way designs are created and validated.

In addition, rules-based Collaborative Design Merge functions provide automated integration of multi-source design inputs at a detailed level, simplifying the task, and raising the efficiency of collaborative design.

DESIGN & PRODUCE:

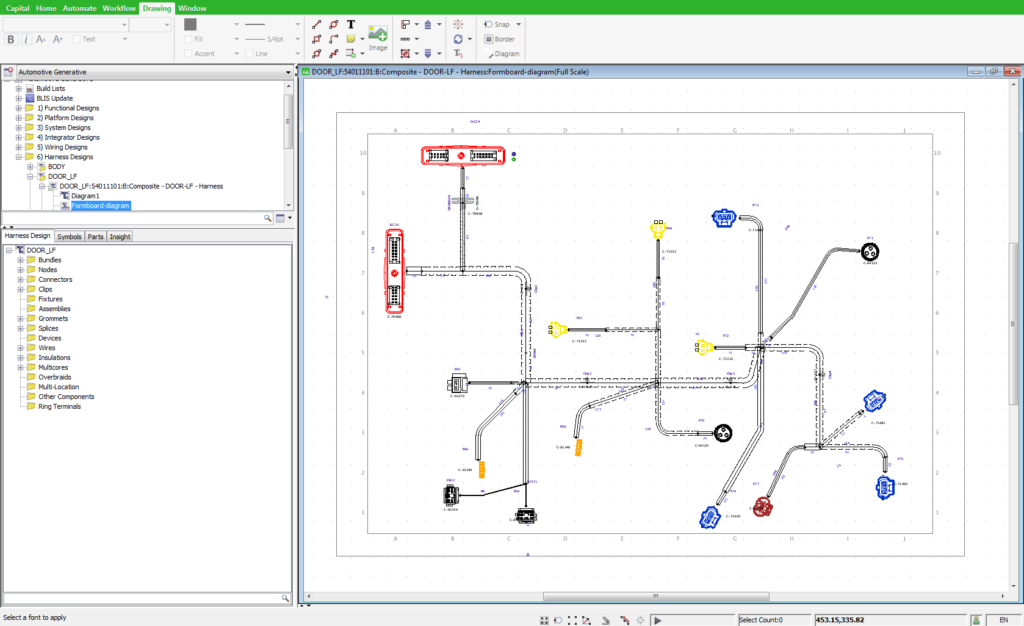

Capital Harness Designer Modular

Capital Harness Designer Modular enables harness engineers to create fully detailed, validated and manufacturing-ready harness designs and modular sub-assemblies.

Buildable harness variants (including diagrams and BOMs) are automatically generated, based on user defined choices for decomposition – Composite-Derivative decomposition, or Modular decomposition. Modular decomposition offers both functional module decomposition, for example “tail lamps”, and production module decomposition, for example “ECU connector sub-assembly”. Conceived from the ground up to be highly configurable, Capital ModularXC allows companies to tailor the tool to meet their precise needs, both in terms of graphical outputs and they way designs are created and validated.

Functional assignation algorithms identify modules based on codes assigned to the wires, then automatically identify and configure all related components – connectors, protections, clips, etc – to complete the definition of each module. Production assignation algorithms identify and configure the set of manufacturing sub-assembly modules, based on user-defined best-practice rules and constraints to increase manufacturing efficiencies and reduce costs.

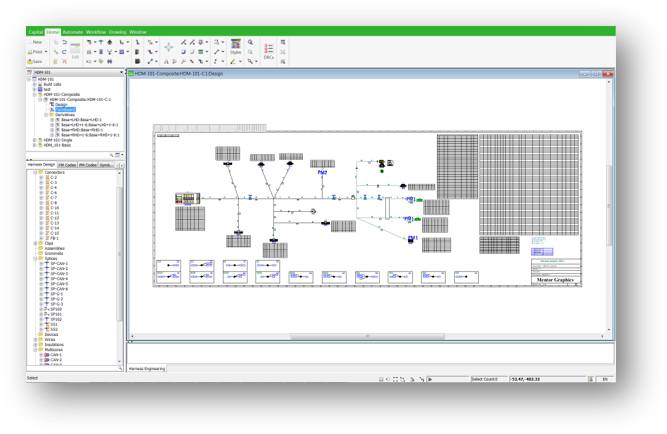

DESIGN: Capital Wiring Integrator

An add-on to Capital Logic Designer, Capital Wiring Integrator provides users with the ability to create a topological view of a vehicle and associate wiring diagrams to this view.

One of the many benefits of having an architectural view of the electrical systems is the ability to control the wire routing and visualize the path of all wires throughout a platform. This makes inline validation much easier, early calculations of bundle diameters and provides back annotation of wire attributes, such as length, into the Capital Wiring Integrator designs. These wiring designs can then be analyzed to ensure electrical design objectives have been met.

Adding Capital Wiring Integrator to the Interactive flow provides electrical systems designers with an additional level of design abstraction that provides them the ability to understand the overall effect of the platform wiring on the harness architecture. The ability to share harnesses data directly with other Capital applications or MCAD tools greatly reduces the amount of time required for harness definition.

Capital & Capital Essentials

Professional Services

Technology will never stop evolving, it’s the nature of the beast. So having an innovation advisor on your side is vital: to tailor a strategy that fits, and to uncover the right tech for your toughest business problems—no matter the industry.

Our technology consulting services help you steer your transformation with the latest technology, design thinking and agility, while also energizing your legacy systems—at a pace that’s right for your business. Raise your business to the next level with groundbreaking strategy, fresh technologies and innovation advisors that help drive business value.

What's Expert Partner?

Plan

Prepare

Perform

Services & Training

For technical software used in the design of electrical distribution systems the key factor seems to be how the organization adopting the software organizes itself. That may seem a curious thing to say, but let’s look at it right from the beginning.

Technology Advisory Services

Offering a comprehensive approach to deployment:

- Expert-led

- Expedited & Streamlined

- Continuous Verification & Validation

- Accelerate time to improved productivity

Read more about our Software + Services

On Demand Training

Courses include interactive videos, written course materials, knowledge checks, and hands-on labs through the Siemens Xcelerator Academy platform. This platform utilizes a test environment where you can work with the tools in a hands-on setting, allowing you to implement the skills you're gaining along the way.

instructor led Training

#1- Dynamic, real-time engagement with an instructor. We deliver classes with all the necessary equipment and software at your offices.

#2 - Training without the travel. This flexible learning format is delivered with a qualified instructor available online to answer questions and walk you through Virtual Labs running fully configured Siemens software.

Implementation & Library Development

Our technology advisors help you pivot wisely to new technology, while getting the most from your legacy technology. Together, we develop a roadmap for change that integrates with your workforce and business processes creating greater success.

Quick Start Services

Read more about our QuickStart Library Services

Symbol Libraries

Component Library

A QuickStart custom library of 100 existing connectors of your choice (together with some bonus content) which is usually a good start for a new customer and includes the time to select, package, test, transmit to you. You can easily “grow” the library yourself from there with proper training.

Oasis maintains 3 master libraries.

- Metric UOM – Automotive

- Imperial UOM – Automotive

- Imperial UOM – Mil-Aero

As of 1/1/2021 there are over 13,000 components in these libraries.